Reinforcement Learning For Dynamic Machining Process Parameters

This project is supported by the Department of Energy

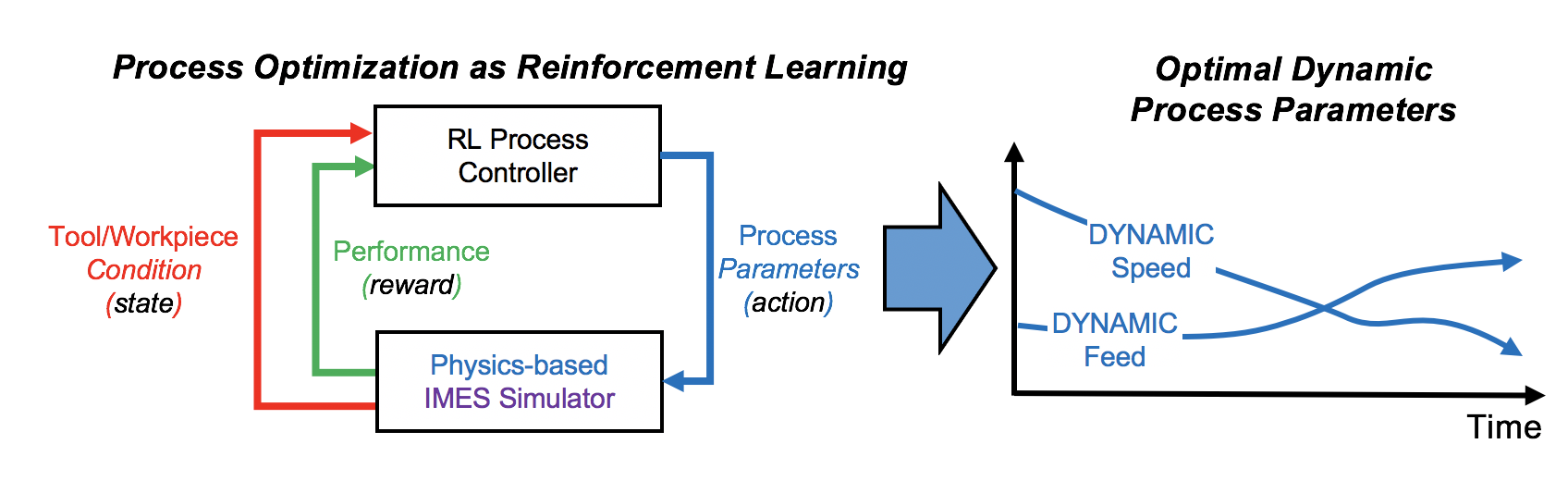

In this work we use model-based reinforcement learning to find optimal dynamic process parameters (speeds and feeds) while machining alloys.

This work pays attention to the effects of tool-workpiece interaction on workpiece quality and overall energetic costs.